Alena Vedernikova

Alena Vedernikova

SPbGASU specialists have developed a program for the calculation of pipe-concrete structures by the "reverse" method. They received a certificate of state registration of the computer program No. 2022663635.

The team of authors included Grigory Bely, Visiting Professor at the Department of Reinforced Concrete and Masonry Constructions, and Alena Vedernikova, Senior Lecturer at the Department of Architectural and Engineering Constructions. We asked Alena Andreevna to tell us why she was interested in pipe-concrete structures and what opportunities the new program for their calculation opens up for builders.

– I have always enjoyed the disciplines "Metal constructions" and "Reinforced concrete constructions". Pipe-concrete structures are composite: they have the advantages of metal structures, such as relatively quick installation, high strength, but they also have the advantage of reinforced concrete structures - fire resistance. When I first heard the name of the topic, I realized: here it is.

My supervisor, Grigory Ivanovich Bely, specializes in non-linear methods for calculating steel structures and light steel thin-walled structures. One day we came up with the idea to look at pipe-concrete structures not as reinforced concrete with a steel part, but as steel with a concrete part. Grigory Ivanovich developed a general calculation method, and I adapted it for pipe concrete and wrote a computer program. In 2021, we published an article in the April issue of the Bulletin of Civil Engineers journal, where we described the essence of the calculation, gave an example and compared with experimental data.

– Where are pipe-concrete structures used?

– Pipe-concrete structures are used where there are high loads - in the construction of bridges and large-span buildings, in high-rise construction. The name of such structures speaks for itself: they consist of pipes and concrete. Thanks to their outer steel shell, concrete pipe structures allow you to erect a building faster, since during the construction phase of the building, part of the load that occurs during installation is taken over by the steel pipe. Another important advantage of pipe-concrete structures is the increased bearing capacity. The round pipe is ideal in its shape under central loading and eccentric loading with a small eccentricity. If you compress concrete inside the pipe, it will try to expand to the sides, but the steel shell will limit this expansion. Since the concrete has nowhere to go, it will stay in a three-dimensional stressed state, giving a pipe-concrete column one and a half to two times better bearing capacity.

– How are the calculations performed to create them?

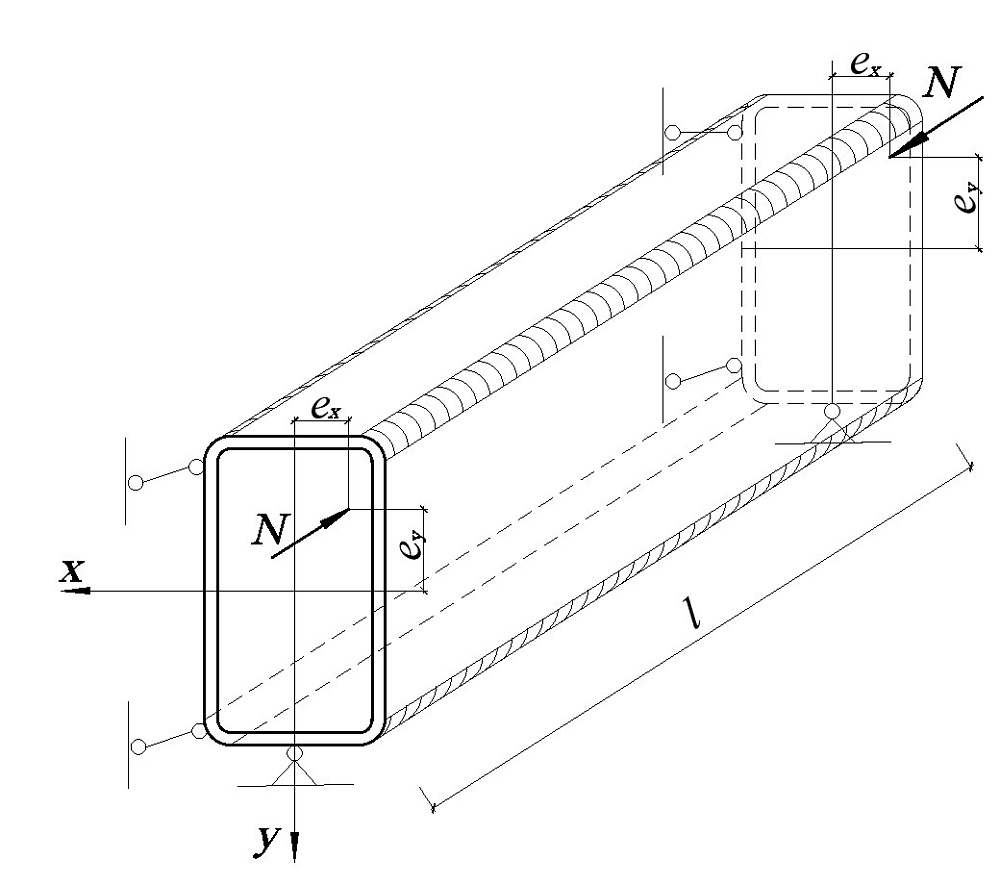

– In modern regulatory documents, a pipe-concrete structure with eccentric compression is considered as reinforced concrete. There are two calculation options - according to the limiting equilibrium of the most loaded section and according to the non-linear deformation model (NDM). These techniques make it possible to calculate structures for strength, and when calculating for stability, the calculation is reduced to the strength of sections. Often in this case, the transverse movement (deflection) of the element is taken into account only by the eccentricity coefficient. The eccentricity factor is partly based on empirical data and the average bar stiffness. However, steel pipes do not actually reach a plastic hinge state when working in a structure. Therefore, the NDM for calculating such sections is more consistent with the essence of the stress-strain state. It is clear that 30 years ago engineers did not have such extensive access to calculations and structural modeling on a computer, but now the methods can be improved and calculated directly, taking into account the actual rigidity in dimensionless quantities.

– Can these shortcomings be eliminated?

– The norms include the average stiffness obtained empirically. It gives a simple calculation, but is more conservative. The peculiarity of our method is that it is more accurate, since it takes into account the actual stiffness in each calculation. The method is close to the methods of nonlinear calculation, as, for example, in the ANSYS program.

Its second feature is that it is reverse. In direct methods, the load and how the structure will behave is unknown. The reverse method has fewer unknowns. We set the ultimate strain, assuming the bar is absolutely elastic, and then separate the actual and fictitious load in the general elastic load case. We have a simple calculation form - a small table in Excel and a concise program code. This form is convenient, visual and has not yet been used to solve such problems.

Our method speeds up calculations several times. I would like the software to be used by design engineers. Now we have passed the stage of registration of the second version of this program.