SPbGASU Created a New Device to Control the Indoor Temperature

Artem Patrin

The team of authors from SPbGASU, which included Artem Patrin, a sixth-year student of the Faculty of Civil Engineering, Tatiana Rogozhina, Associate Professor at the Department of Physics and Chemistry in Construction, and Vladimir Dronov, Senior Lecturer at the Department of Physics and Chemistry in Construction, created a new device for controlling indoor temperature. They received the patent 201884 "Indoor temperature control device". We talked with Artem Patrin and found out what are the features of the solution proposed by the scientists.

– The indoor temperature determines the quality of life, affects the efficiency of people and mechanisms. It is necessary to control the temperature for the rational use and economical use of fuel and energy resources. There is a great amount of temperature control systems, but most of them consume electricity, which leads to additional costs. We proposed to remove excess temperature in residential and non-residential premises by installing an automatic ventilation system that does not require electricity, which can significantly reduce costs.

– How long have you been working on this topic? Why did you choose it?

– I have always been interested in new discoveries in physics. In 2015, during my studies at Lyceum No. 13 in Troitsk, Chelyabinsk Region, my Physics teacher Olga Radievna Sukhova suggested studying a new material, which is obtained from nylon threads by twisting. The peculiarity of the material is that when heated, the length of the resulting fibers decreases, which is not typical for most materials. Under the guidance of Olga Radievna, I wrote the scientific work "Creation and study of the properties of an artificial muscle from a fishing line." Later, I continued my research under the guidance of the teacher of Robotics Maksim Aleksandrovich Dergunov, and we managed to automate the process of fiber production by creating a stand.

At SPbGASU, Tatiana Sergeevna Rogozhina and Vladimir Mikhailovich Dronov became my mentors and co-authors. Significant assistance in understanding the operation of a temperature-sensitive power drive was provided by Doctor of Engineering Sciences, Professor at the Department of Reinforced Concrete and Masonry Constructions Lev Marlenovich Kagan-Rozentsweig. Later, I used the developments gained in my school years in patented utility models.

– What exactly did you propose?

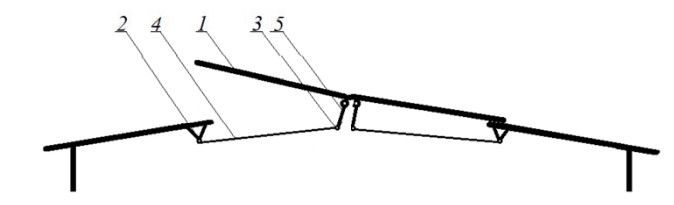

– The novelty of the invention is the use of a new heat-sensitive power drive - harnesses made of nylon fiber. The use of this material made it possible to eliminate the consumption of electricity and significantly reduce the inertia of the mechanism, due to which the response time to temperature changes was significantly reduced in comparison with analogues using hydraulic cylinders. In addition, the disadvantages of the previous patent 184506 developed by us “Device for maintaining the required temperature range in a greenhouse”, which has a similar principle of operation, were taken into account. Thanks to this, the new utility model is more reliable when working in strong wind conditions. {gallery name="патрин"}

Patent

– How did you conduct the research?

– We analyzed the existing works on the creation of thermal fibers from polymers, patents of ventilation systems, and developed a device for the manufacture of thermal fibers from polymers. In this device, a nylon monofilament is attached at one end to an electric motor. A load is suspended from the second end, fixed on a rail movable in the vertical direction, which eliminates untwisting and allows you to create tension in the thread. When a certain amount of deformations is accumulated, the monofilament loses its stability and forms a coil. The number of turns gradually increases until the turns reach the top end of the thread. The resulting sample is a thermally driven fiber. After twisting, the sample is attached to the fixing frame in close proximity to the heating element, and then the fiber goes through three heating cycles in order to relieve residual stresses.

Next, we created a device for isometric studies. When heated, the fiber, fixed with a mounting plate to the hook of the force sensor from one end and to the body with the help of a mounting plate from the other, contracts and creates a longitudinal force without changing the length. The temperature was measured using a temperature sensor fixed near the monofilament. Carrying out isometric measurements made it possible to exclude the effect of tension from the load, which could distort the measurement results.

Experiments were carried out to establish the dependence of the output force on the length of the bundles and their number, to determine the optimal temperature range. In addition, studies were carried out for samples made from nylon fibers of different diameters. The thinner the harness, the faster the sensor responds. To solve the problem of increasing the speed of the device's response to temperature changes, as well as to improve the efficiency of using the power capabilities of the device, the fibers of the temperature-sensitive power drive were divided into several (two or more) bundles of a smaller section.

– Where can your utility model be applied?

– This utility model can be used both in rooms where there are people, and where people cannot be due to unsuitable conditions. Such sensors make it possible to maintain a certain temperature regime in heated rooms by automatically changing the area of the device for air inflow - for example, as an automatic device for maintaining the temperature regime of greenhouses and hotbeds. And also in other areas where automatic control of the cross section of supply ventilation devices is required.

Text: Tatiana Petrova

Photo: presented by Artem Patrin

✔ Learn more about the SPbGASU Faculty of Civil Engineering