Vitaly Novikov

Vitaly Novikov

Hydrojet technologies are in demand in various industries - from the automotive and aerospace industries to construction. Vitaly Novikov, associate professor at the SPbGASU Department of Forensics, has been designing equipment for hydrojet technologies since 2018. The researcher has 15 published scientific articles, and three more are in progress. This year, he received state registration certificate No. 2024616771 "Calculation of the thermal state of a high-pressure transmitting device for hydrojet technologies."

– Hydrojet technologies are a process of using high-pressure working fluid flows to shape or destroy various materials. These include hydrojet cleaning and drilling, as well as jet grouting – a method of soil stabilization based on the simultaneous destruction and mixing of soil with a high-pressure jet of cement mortar; in this case, the soil and the soil-concrete piles embedded in it are considered as a single geotechnical massif. Using only high-pressure water, it is possible to process soft materials – foam plastic, rubber, paper. For metal, stone, ceramics, abrasive particles are added to the water flow. The advantages of such technologies are that the processing occurs with high precision and without the formation of heat-affected zones that can change the properties of the material being processed, – the scientist said.

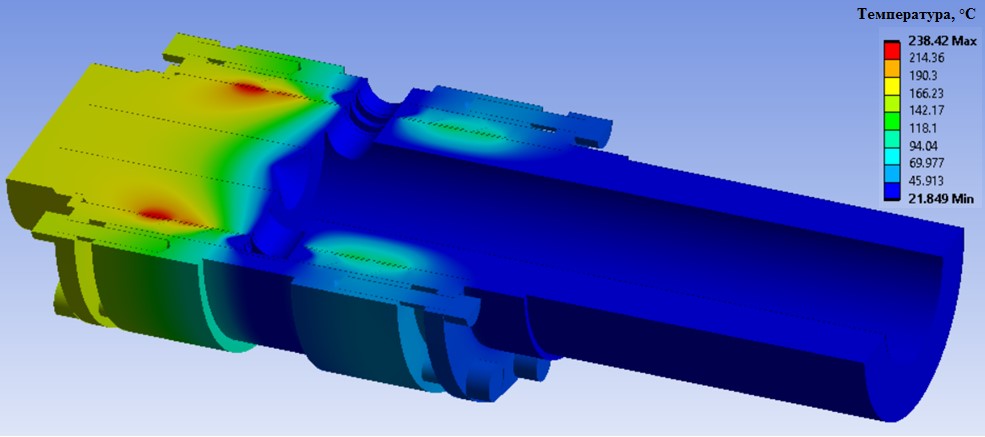

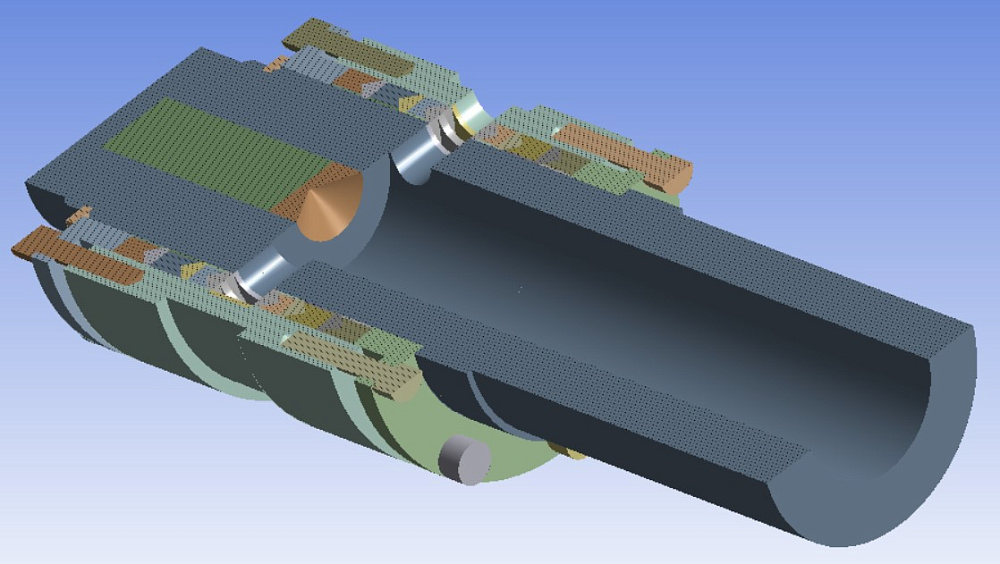

Vitaly Novikov has developed software that allows you to calculate the temperature of the sealing elements in a hydraulic puller depending on a set of parameters and select the most rational option that ensures minimal operating costs. This is achieved by considering the operation of the device from the point of view of the thermal state. That is, the design is created taking into account the factor of how and to what extent the heat released during operation affects the functioning of the device - improves, worsens or has no effect, which no one has done yet. The new software can be used in the design and reliability assessment of structural elements, as well as in the educational process in practical classes. In his work, the scientist used numerical modeling, namely the finite element method based on the obtained experimental data. The tests were carried out at Tula State University in May 2023. Aleksandr Pushkarev, professor at the SPbGASU Department of Land Transport and Technological Machines, acted as a scientific advisor.

The researcher plans to continue his work and create a useful model for this type of device.

The described studies were carried out, among other things, within the framework of a grant for the implementation of research work by SPbGASU research and teaching personnel in 2024.

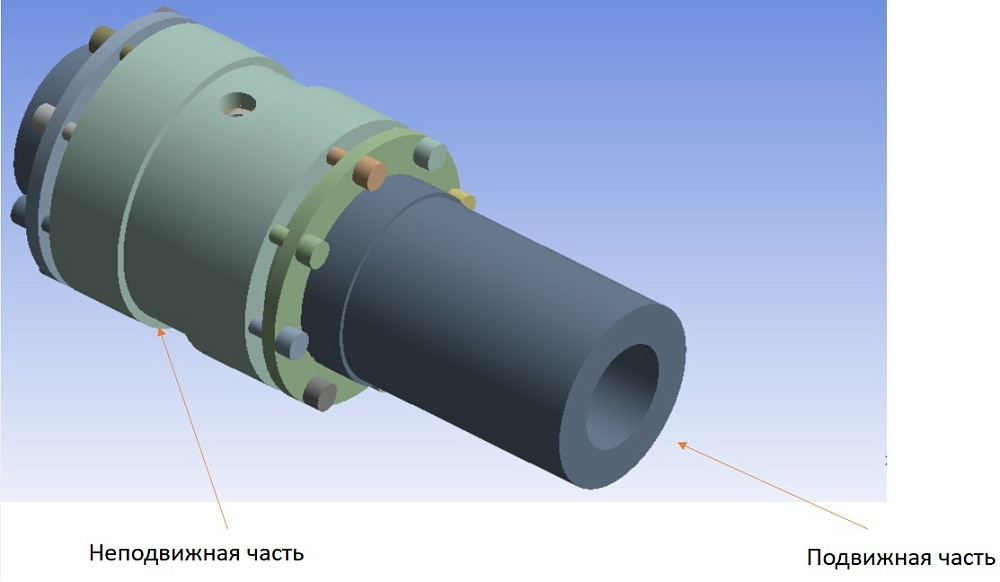

– вертлюг, b) гидросъёмник для струйной цементации грунтов.jpg)

– вертлюг, b) гидросъёмник для струйной цементации грунтов.jpg)