Mikhail Zhavoronkov, associate professor at the Department of Technology of Construction Materials and Metrology, completed the research work "Study of the influence of dispersed reinforcement parameters on the behavior of fiber-reinforced concrete under load" as part of the grant competition for the implementation of research work by scientific and pedagogical staff of SPbGASU in 2024.

Fiber-reinforced concrete has a number of advantages over traditional concrete and reinforced concrete. According to various sources, fiber concrete has increased compressive and bending strength, impact resistance, etc. One of the main advantages of fiber concrete is its increased crack resistance – the ability of the material to resist the formation and development of cracks.

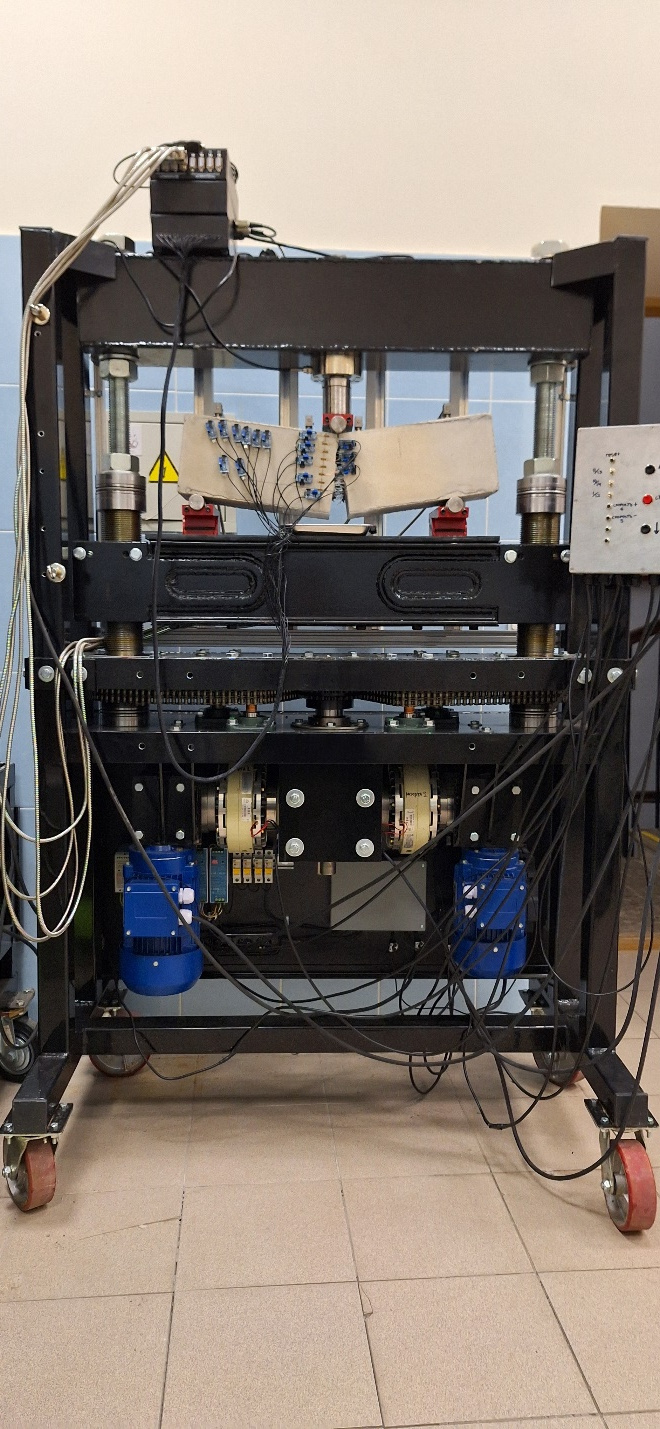

During the study, an original design unit was developed and assembled. The unit allows for three-point bending of fiber concrete samples measuring 150×150×600 mm and monitoring the applied load and sample deflection caused by this load. It also provides the ability to monitor the distribution of deformations along the height of the working section of the sample. The implementation of this capability allowed for measuring the height of the compressed zone of the cross-section of the tested sample and monitoring its change.

The unit includes a loading device and a sensor system. The loading device consists of two crossbars, movable and fixed, and two parallel screw pairs. Simultaneous rotation of the screw pairs causes linear movement of the movable crossbar. A concrete or fiber concrete sample is placed between the crossbars on special stops that ensure its three-point bending. The screw pairs are driven into rotation by a system of electric motors, gearboxes, electric couplings, and a chain transmission. The selection of the leading motor, its speed, and direction of rotation is carried out from the control panel. This is done in such a way as to provide the widest possible range of rotation speed adjustment with minimal loss of torque.

The system of sensors monitoring the behavior of the sample under load during bending includes a strain-gauge weighting device, 4 linear encoders and 16 resistive strain gauges. The sensors are polled alternately, several times per second, and the obtained data are sent to the computer using a simple circuit solution, where they are displayed in the form of corresponding graphs and tables.

The obtained graphs of the dependence of deflections on the applied loads can be used to calculate the force and energy characteristics of crack resistance according to GOST 29167-2021, and according to the readings of strain gauges, it is possible to control the height of the compressed zone at different stages of deformation and destruction of samples.

The properties of fiber concrete and its behavior under load have been studied at the SPbGASU Department of Technology of Construction Materials and Metrology for decades, including within the framework of the scientific school "Nanostructured modification and dispersed reinforcement of building products and structures". At present, much attention is paid to the topic of theoretical modeling of the behavior of fiber concrete under load. In the course of developing this topic, questions arose about the exact determination of the number of fibers involved in the work of fiber concrete under load. In particular, the unit described above was developed to determine their number.

The data obtained during the study can be used in the design of fiber-reinforced concrete structures and form the basis for further research, and the mastered testing methods can be implemented during the educational process as part of laboratory work in the relevant disciplines.